Get in touch with us:

+49 5151 1040

info@reintjes-gears.de

Service Hotline

+49 5151 104104

REINTJES GmbH

Eugen-Reintjes-Straße 7

31785 Hameln

Or use our contact form:

Our next trade fair dates

03/10/2026 to 03/11/2026

TTB

Mobile, US

03/25/2026 to 03/27/2026

Asia Pacific Maritime

Singapore

04/22/2026 to 04/24/2026

NN Logistica

Manaus, Brazil

04/22/2026 to 04/24/2026

Sea Japan

Tokyo, Japan

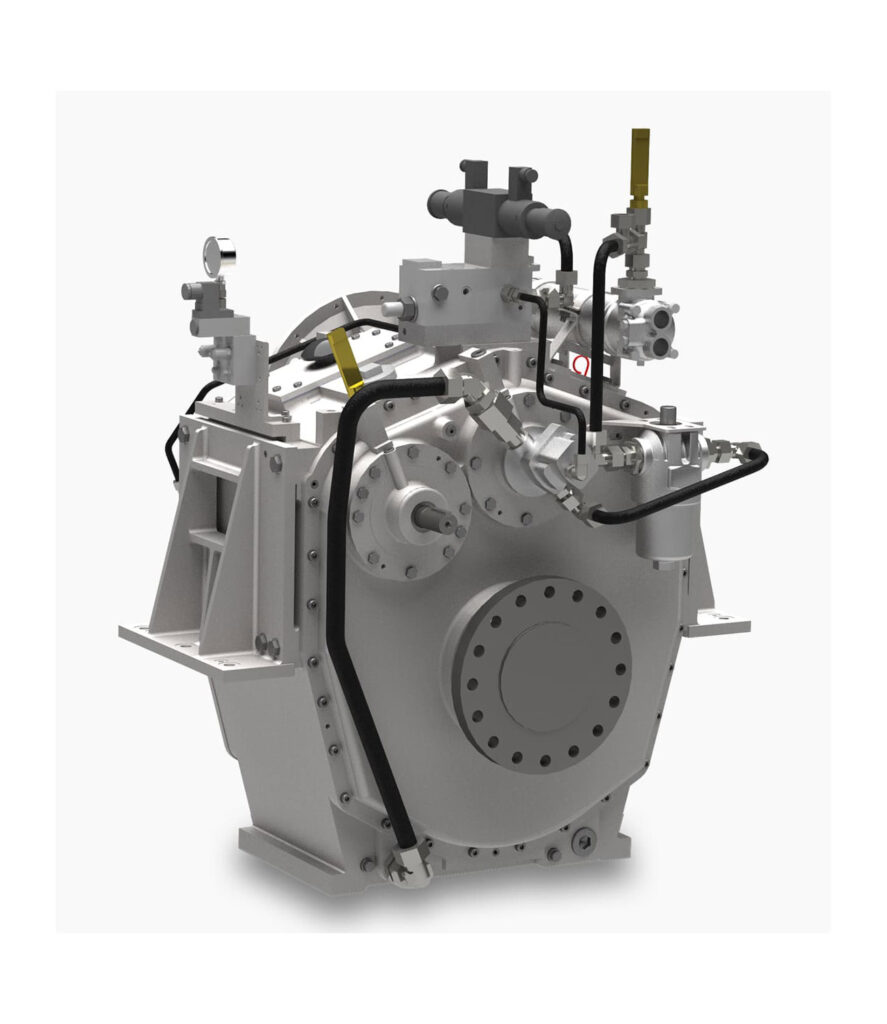

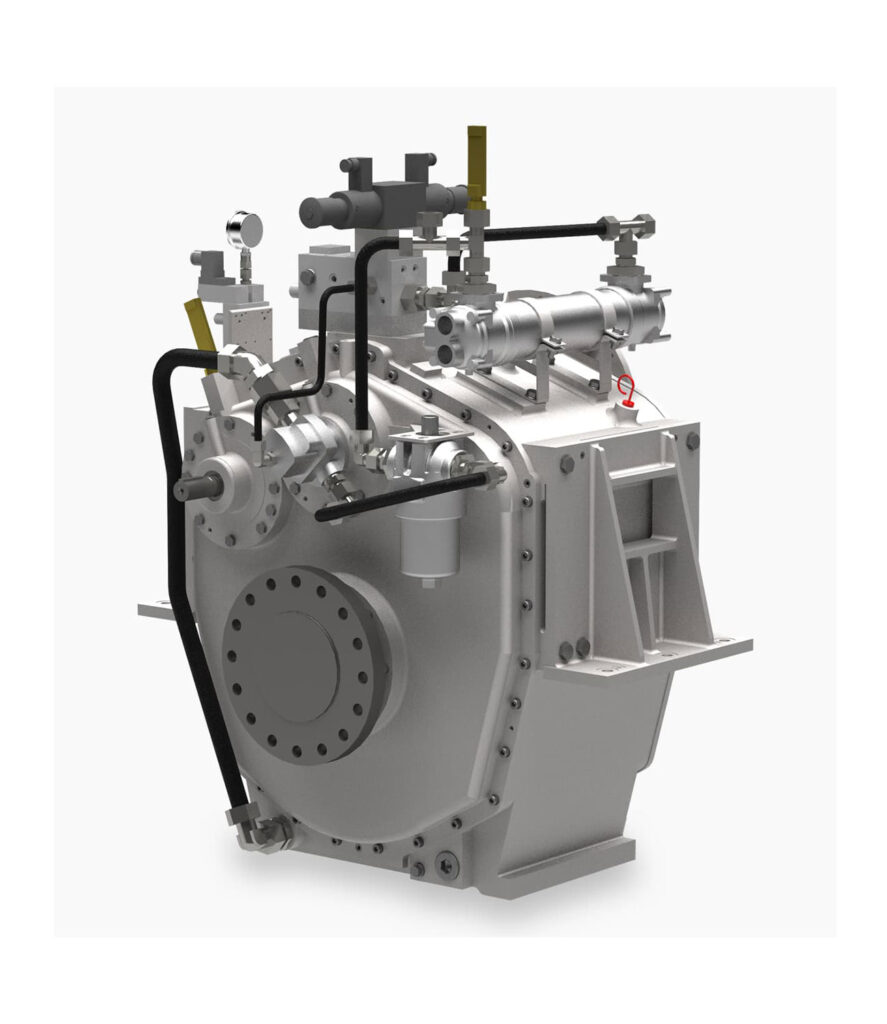

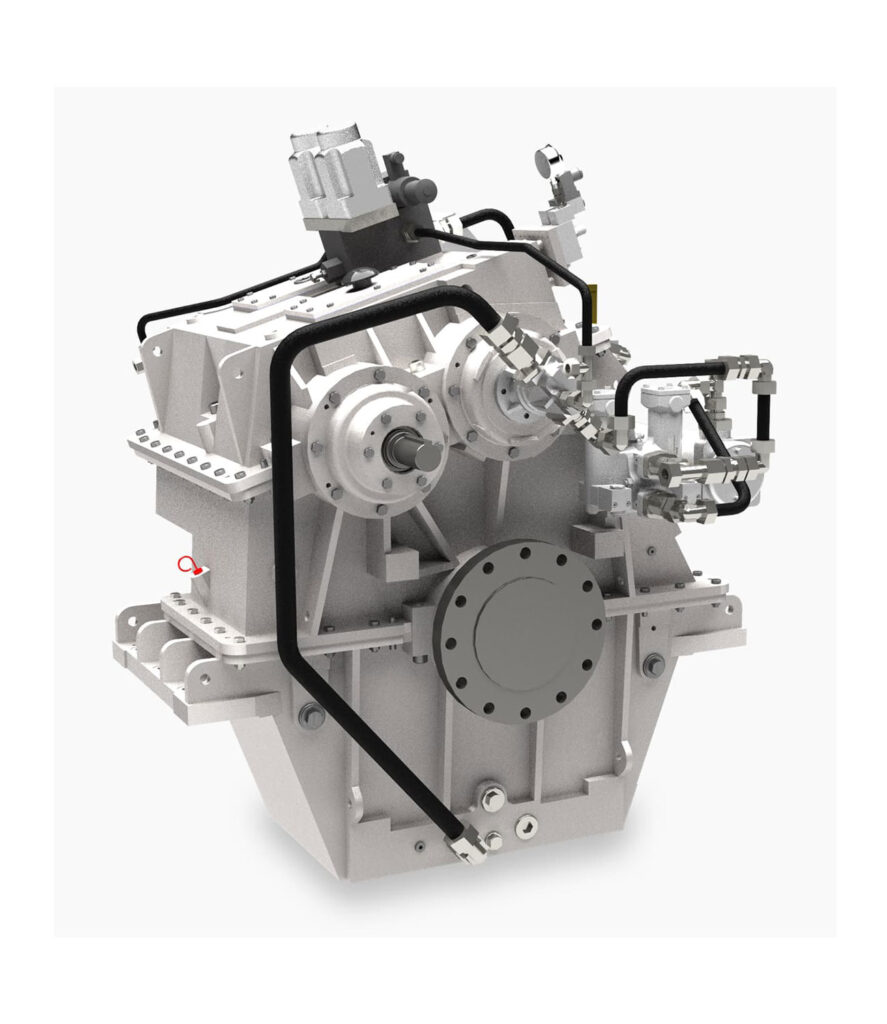

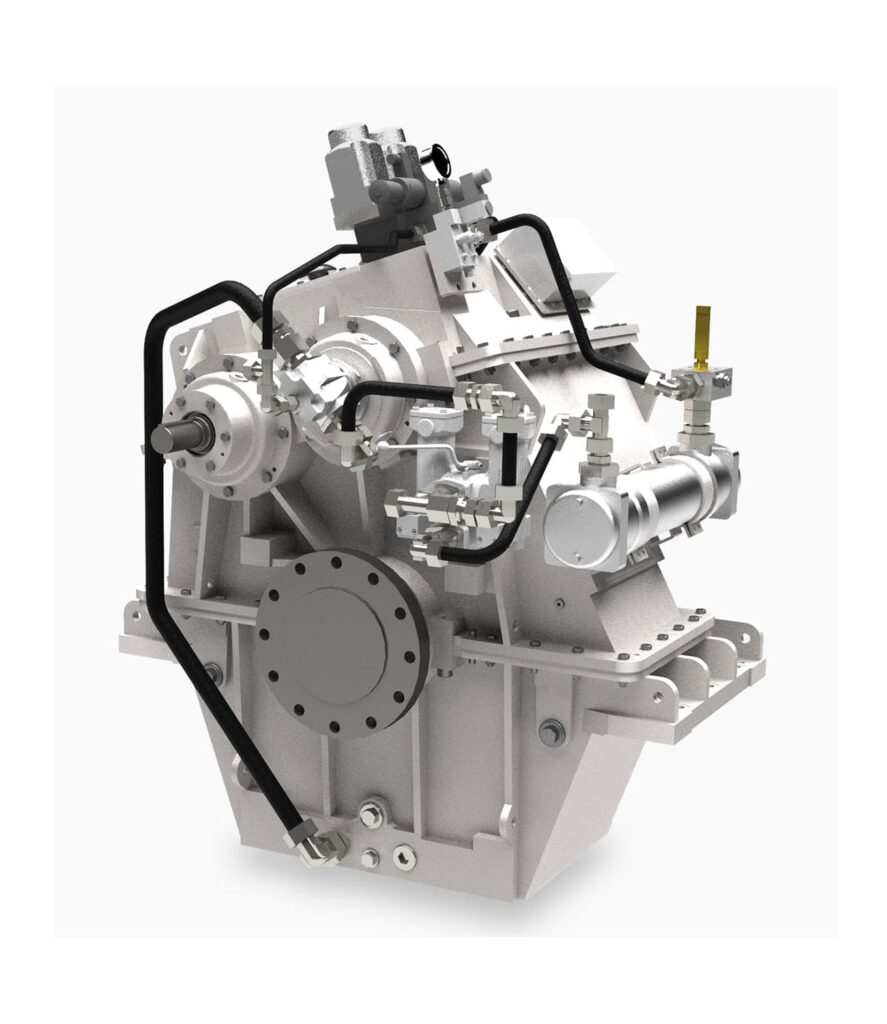

WAF 164 - 7760

Duty Cycles

Continuous Dutyx

Continuous operation with little or no variations in engine speed and power.

Average engine operating hours limit:

unlimited

Allowable hull forms:

displacement

Allowable applications:

commercial vessels

Medium Dutyx

Intermittent operation with some variations in engine speed and power.

Average engine operating hours limit:

4,000 hours/year

Allowable hull forms:

Planing, semi-planing, displacement, catamaran

Allowable applications:

Private, charter, commercial craft (example: crew boats, high speed ferries), navy and governmental vessels

Light Dutyx

Intermittent operation with large variations in engine speed and power.

Average engine operating hours limit:

2,500 hours/year

Allowable hull forms:

Planing, semi-planing, displacement

Allowable applications:

Private, charter, sport and pleasure craft, navy and governmental vessels

Pleasure Dutyx

Intermittent operation with very large variations in engine speed and power.

Average engine operating hours limit:

500 hours/year

Allowable hull forms:

Planing, semi-planing

Allowable applications:

Private, noncommercial, noncharter, sport and leisure craft

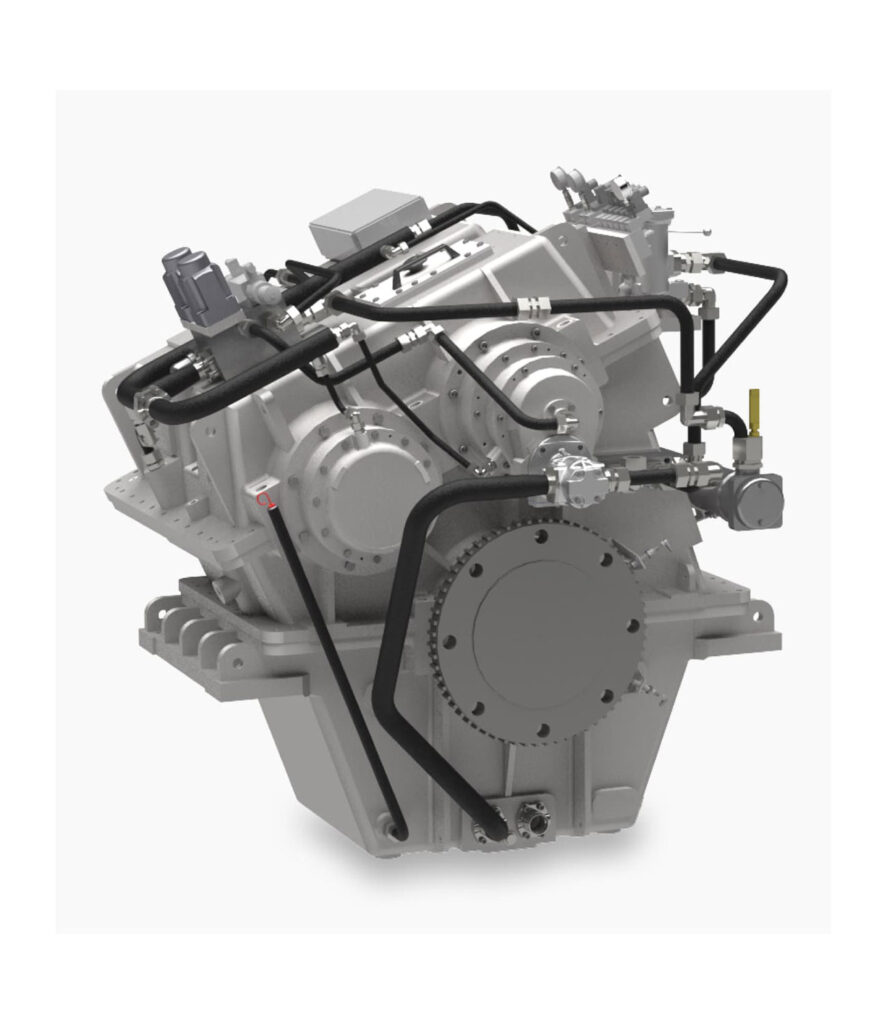

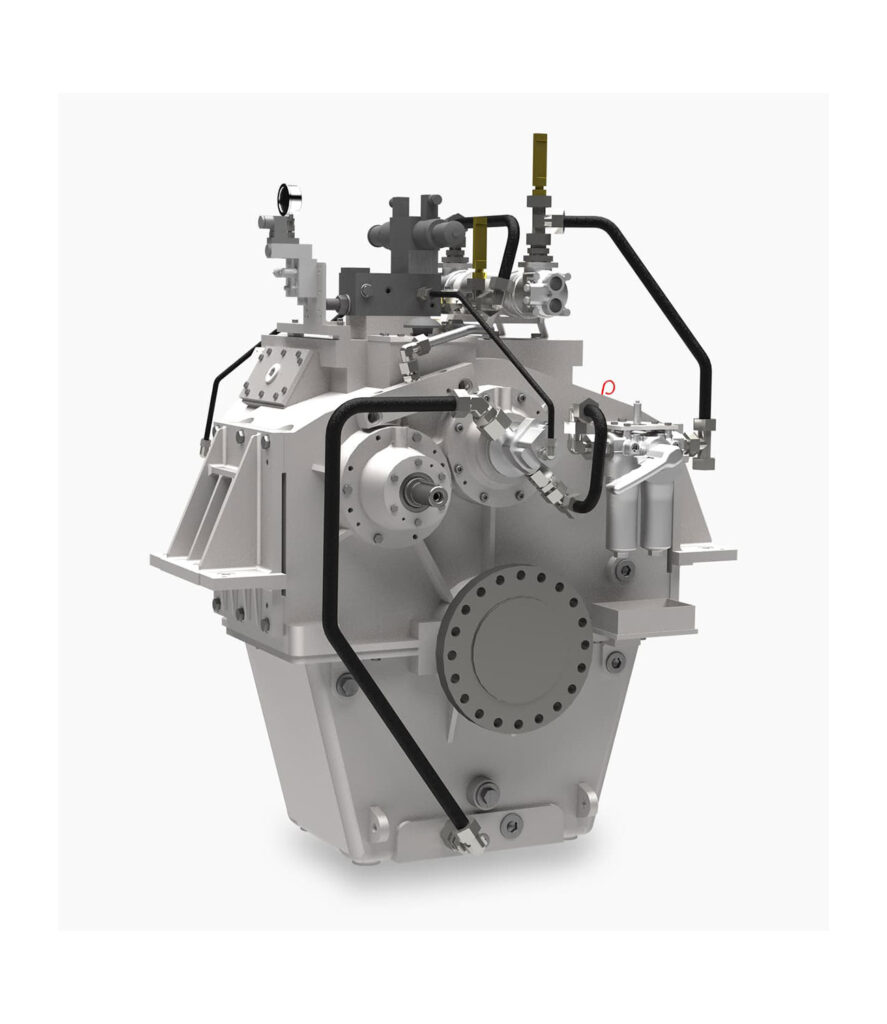

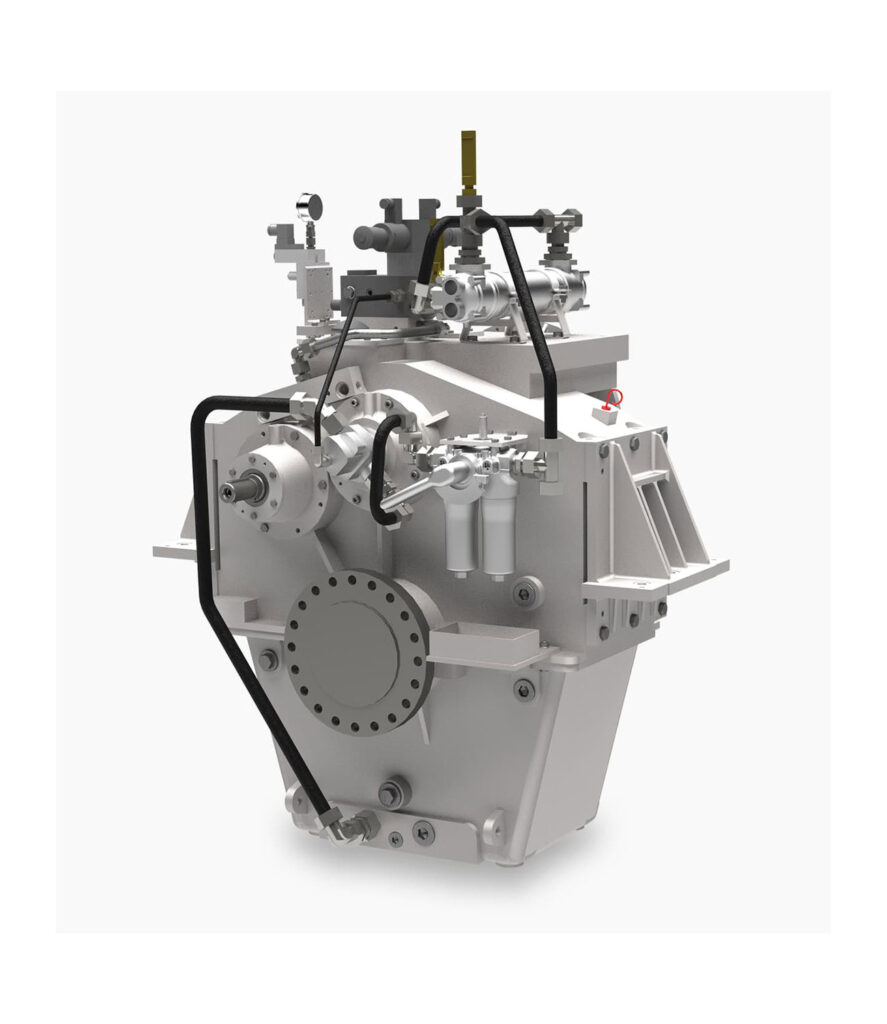

The WAF series gearboxes have been specially developed for heavy-duty use in workboats such as inland vessels, tugs, fishing vessels, ferries, and special vessels with similarly high requirements. The hydraulically shiftable reversible reduction gearboxes are optimized for use in fixed propeller drive concepts.

Subject to change without notice.

Versions

- Grey cast iron housing

- Helical gears, case-hardened and tooth-flank ground

- Built-in, hydraulically actuated disc clutches

- Roller bearings, integrated thrust bearing

- "Fast Clutch" system (WAF 164 - 573)

- Full power transmission in both output directions

- Integrated oil sump, common oil circuit for operating and lubricating oil, oil pump and oil filter accessible from the outside

- Rigid mounting (WAF 573 - 7760)

- Built-on heat exchanger, seawater-resistant, with fixed piping

- Maximum cooling water inlet temperature of 32 °C (90 °F)

- Connection for remote pressure and temperature supervision

- Built-on control valve with electric (including manual emergency operation), pneumatical or mechanical operation

- Input: free shaft with 1:30 cone

- Output: forged-on flange

- Coated with synthetic resin varnish, colour: RAL 7001 silver-grey

- SAE bell housing (WAF 164 - 763)

- Output-side counterflange

- Input-side engine flange

- Flexible coupling

- Approval by classification societies

- Supervision instruments for unmanned engine room

- Heat exchanger for cooling water inlet temperature of > 32 °C (90 °F), compatible with engine cooling circuit

- Trolling propulsion system (ADS)

- Resilient mounting (hard or soft)

- Screwing surfaces for customer-side fastening

- Special gear reduction ratios, acoustically optimised gear teeth

- Connection for electric stand-by pump

- Trailing pump (mechanical or electric)

- Integrated shaft brake

- Auxiliary drive (PTO) incl. SAE pads

- Auxiliary drive (PTI) incl. SAE pads

- Housing made of welded steel

- Yacht premium design: product finish and painting

- Coating with synthetic resin varnish in all RAL colours