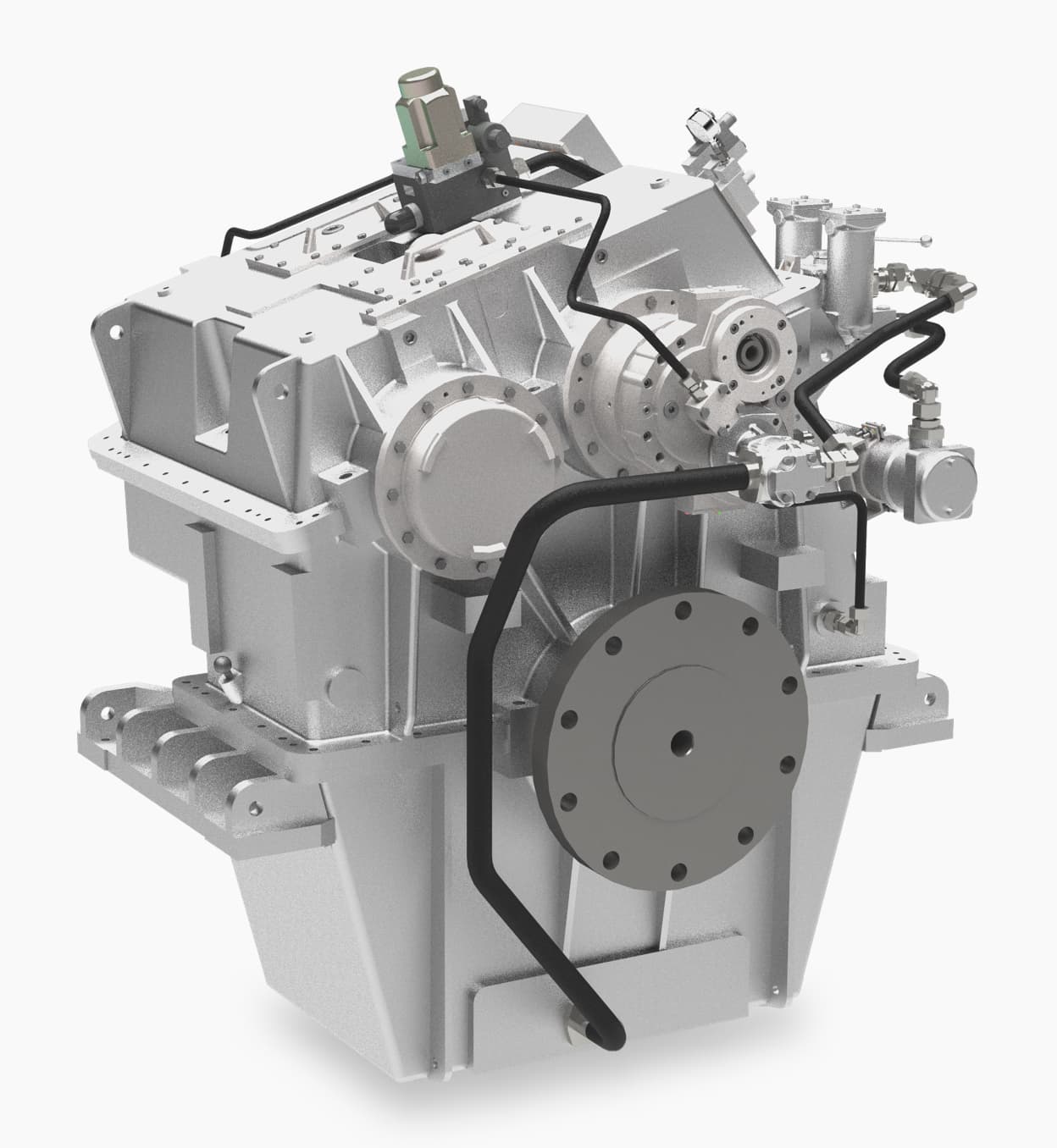

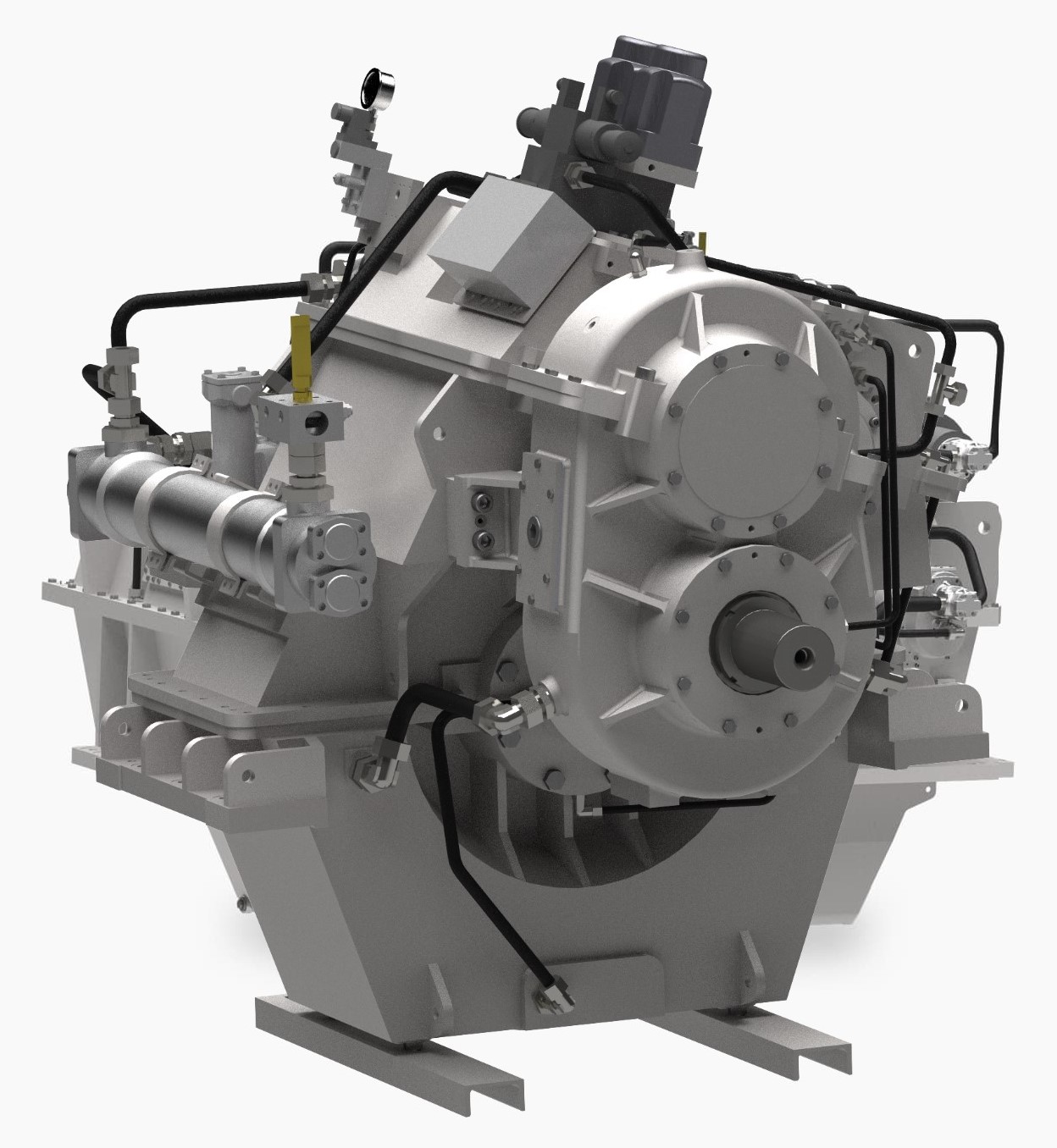

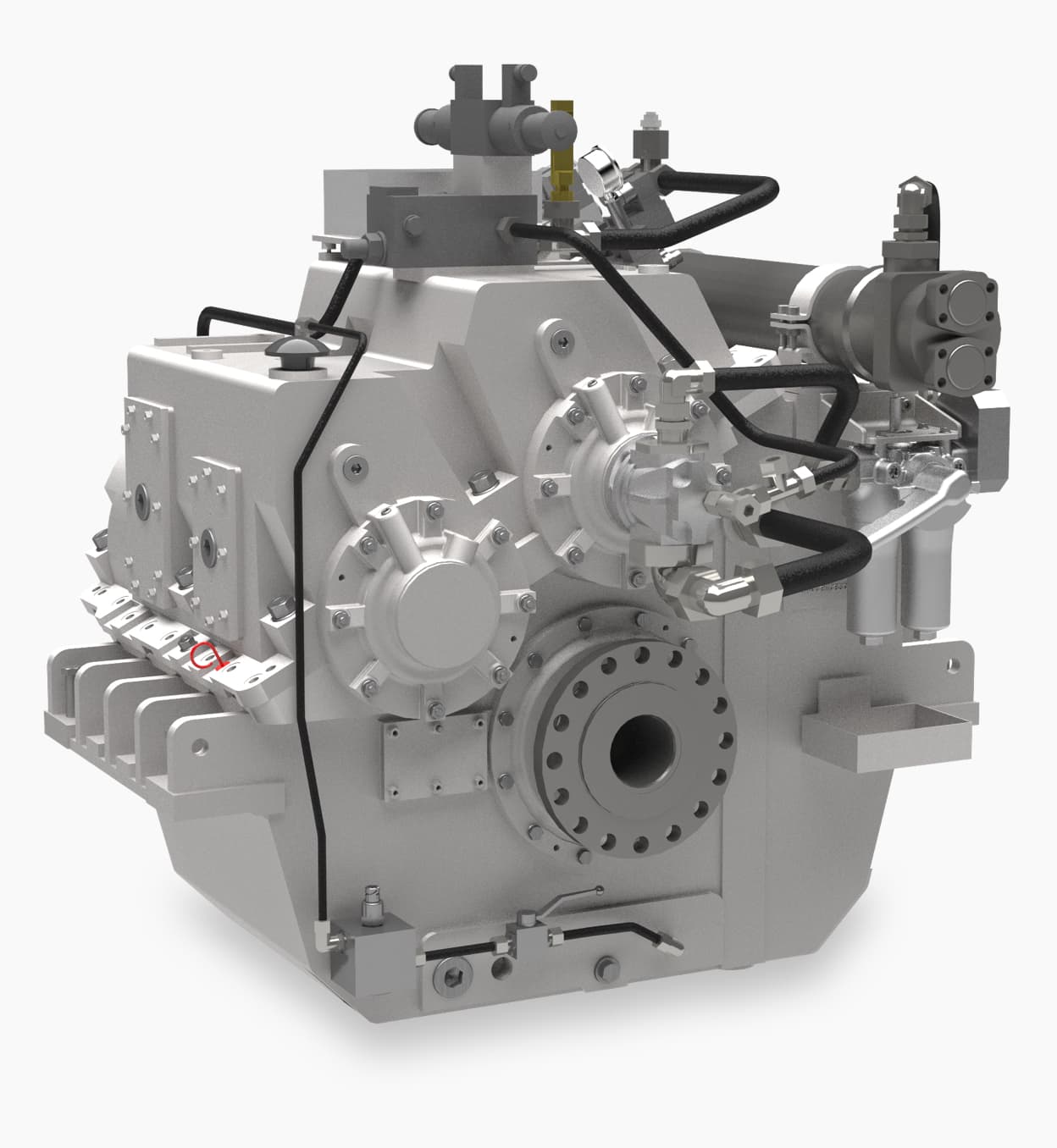

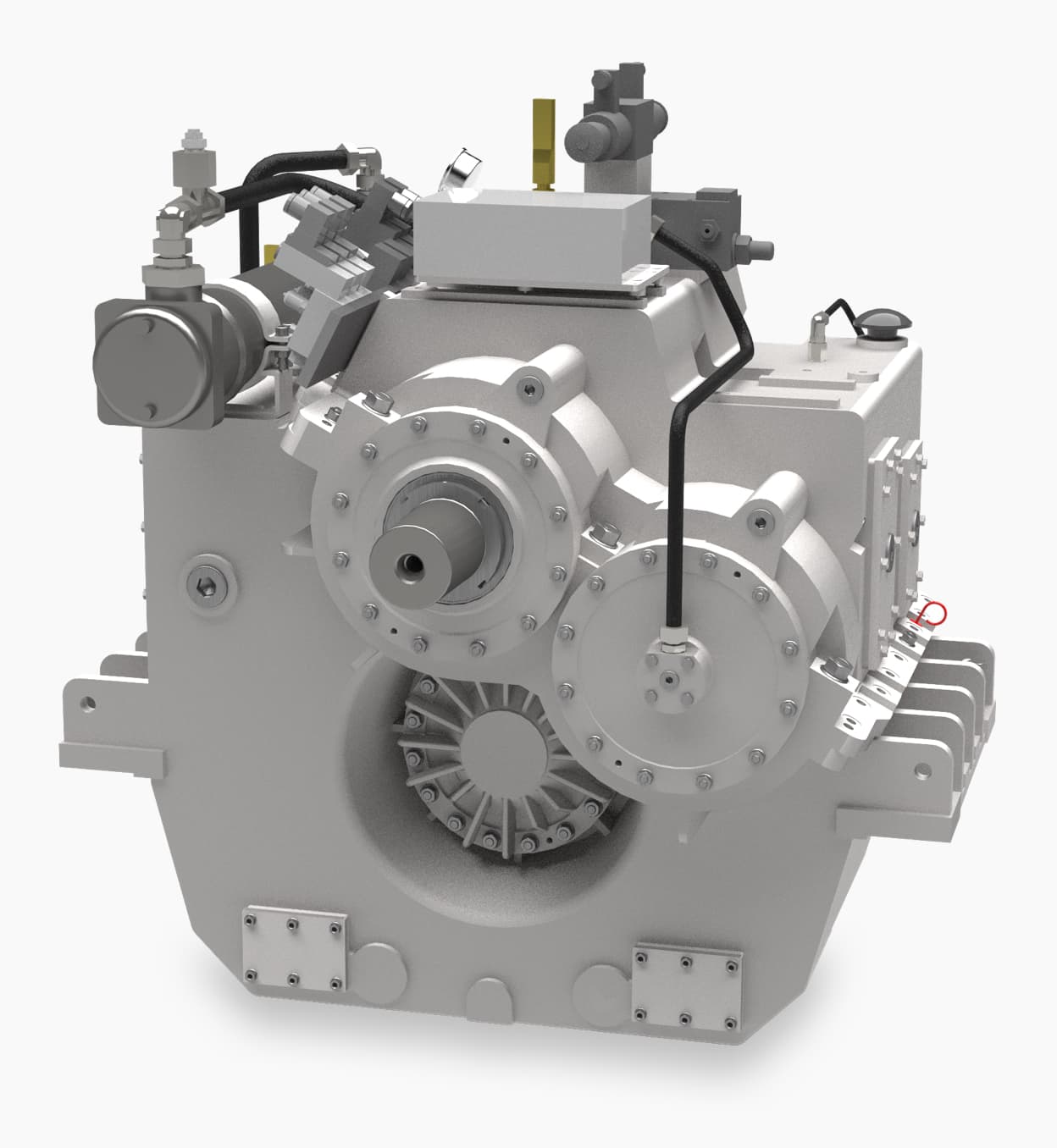

WLS 234 - 2240

Gearboxes of the WLS series have been specially designed for fast vessels such as naval units, patrol boats, yachts and other vessels with similarly high performance demands.

Subject to technical modifications.

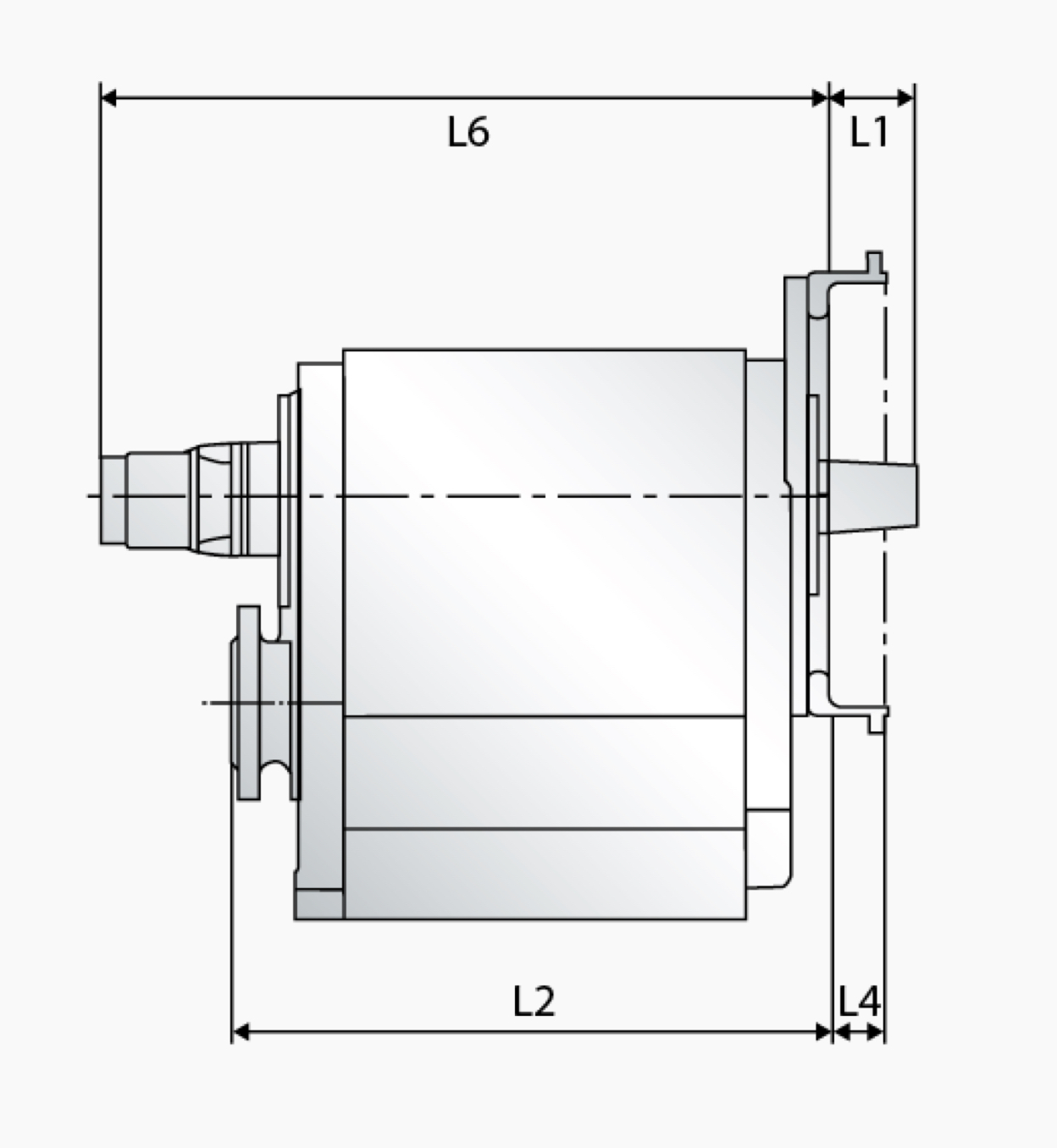

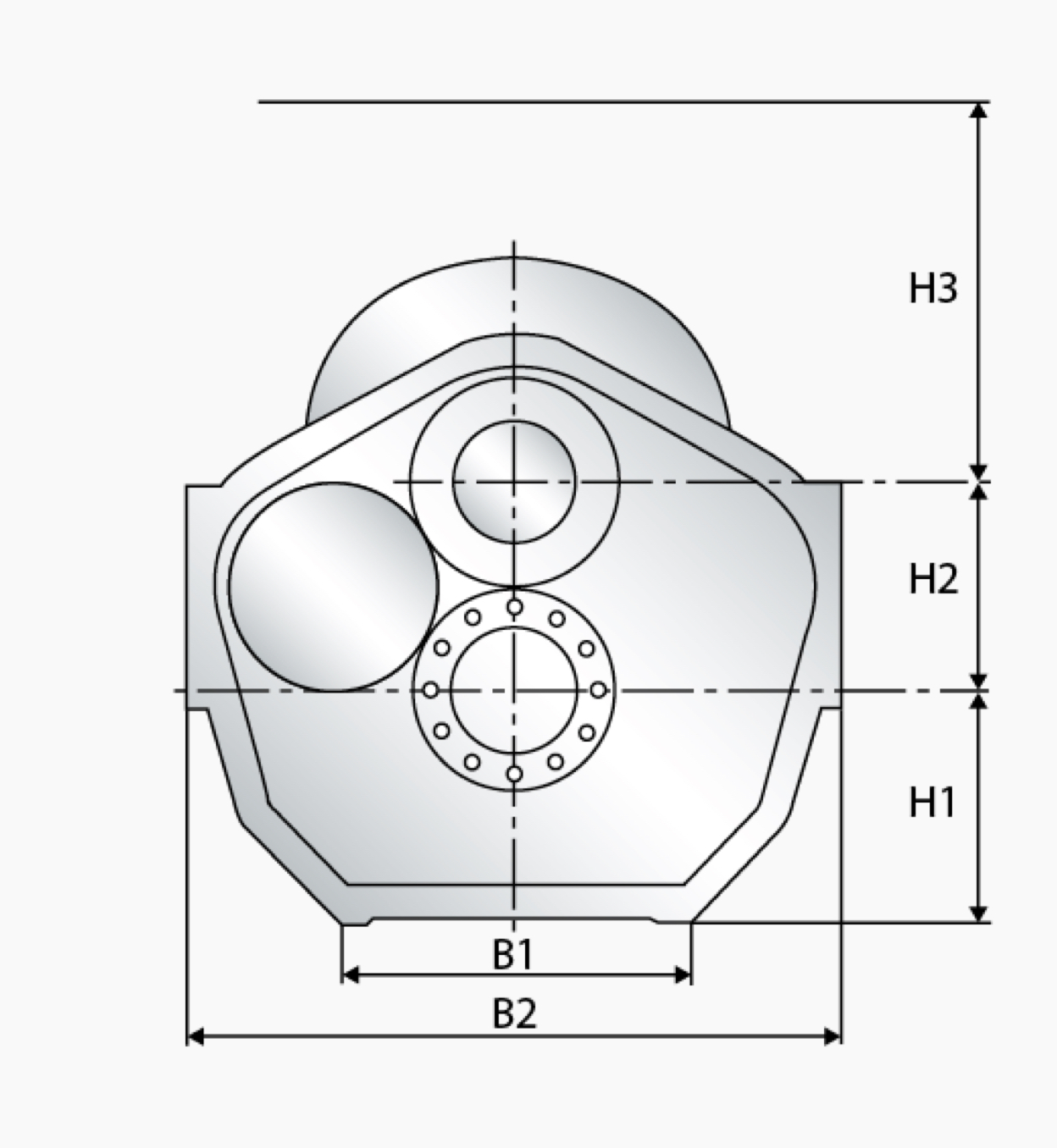

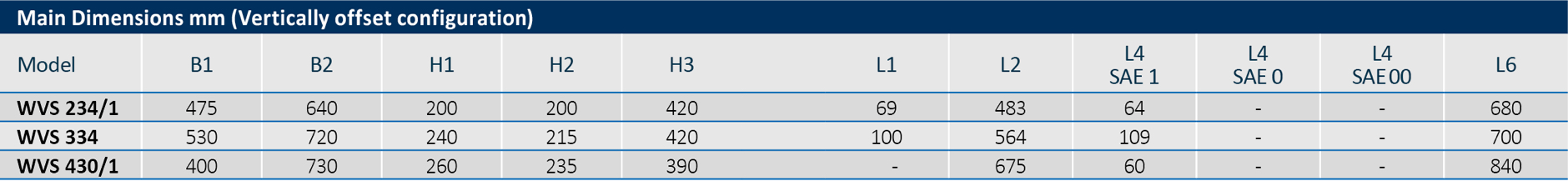

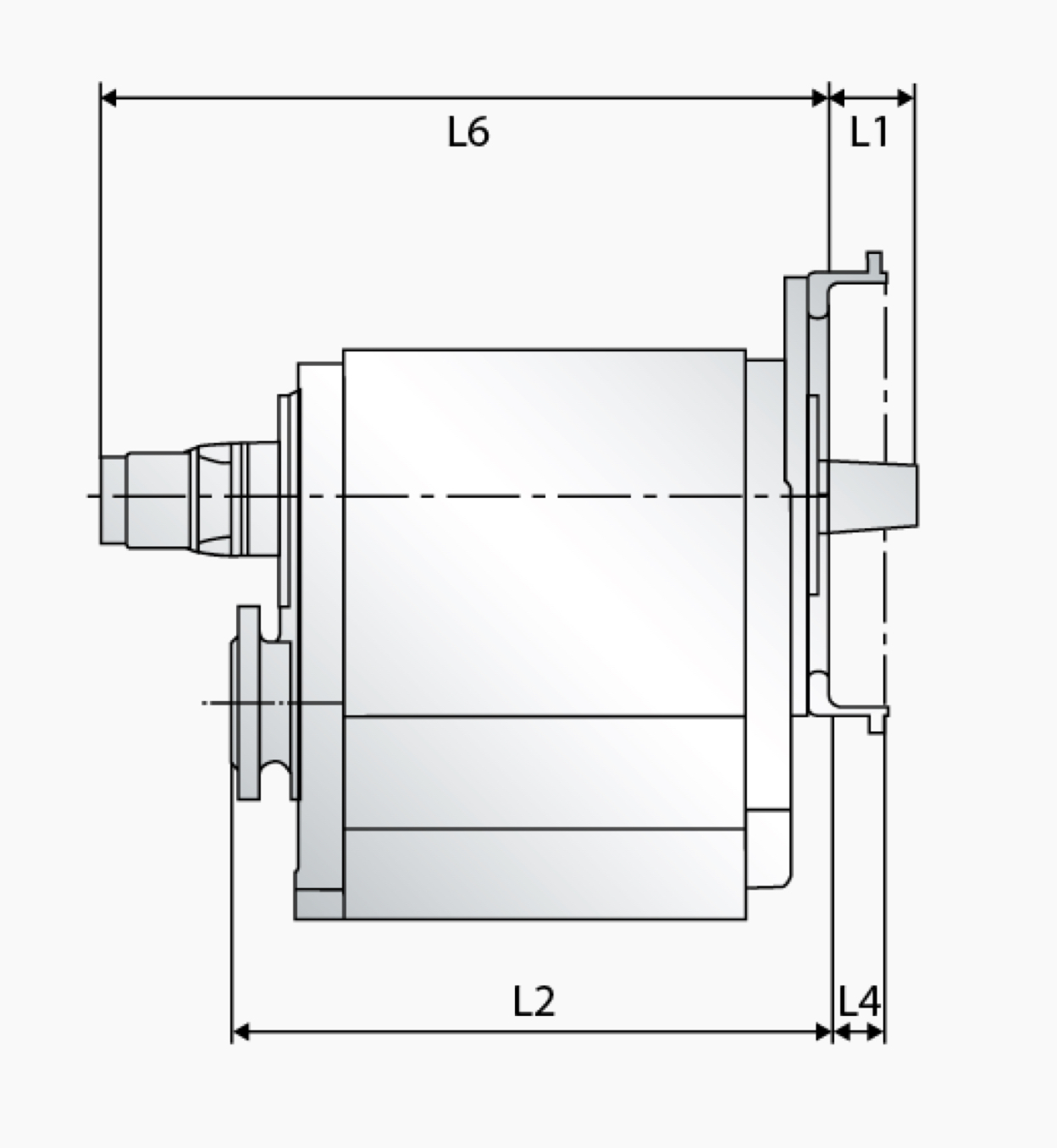

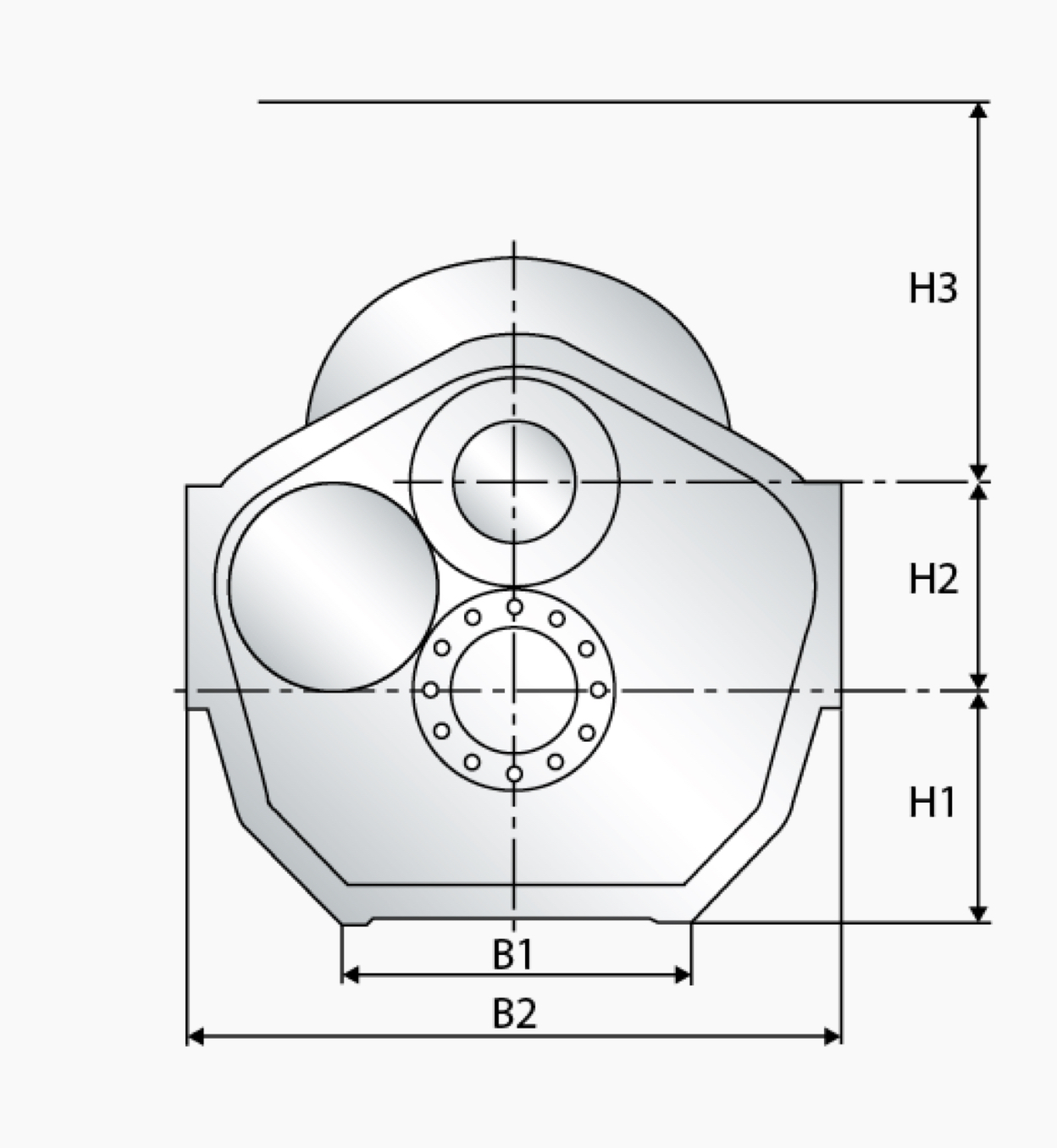

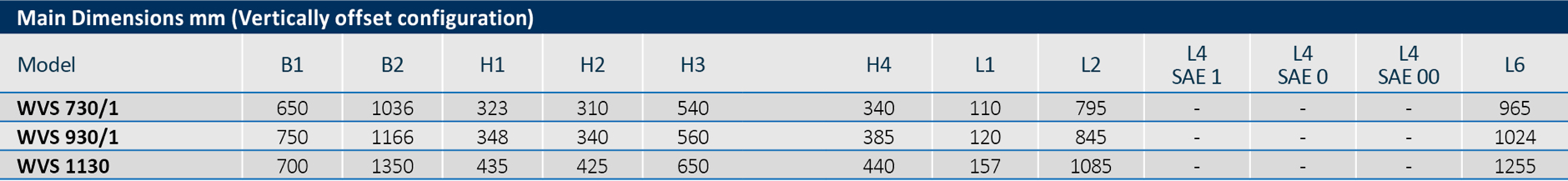

Main Dimensions

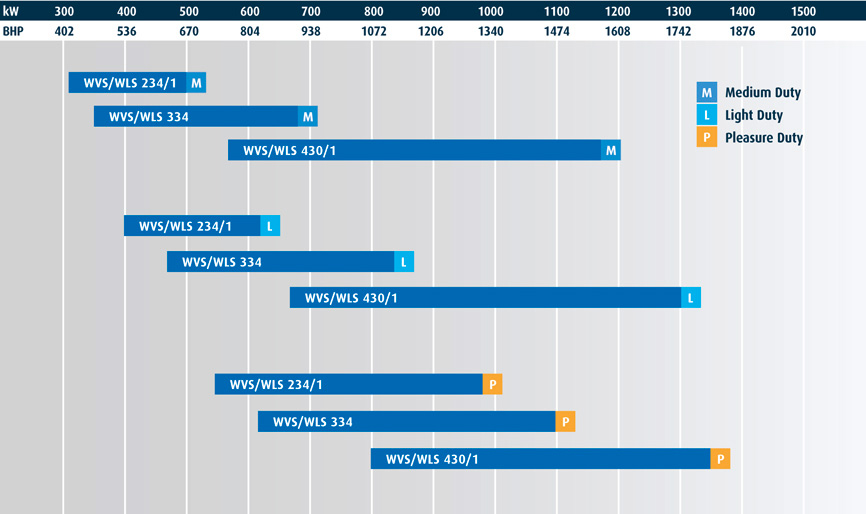

Ratings

Versions

- Housing made from aluminium alloy

- Prepared for mounting of SAE bell housings

- Spur wheels helically toothed, case-hardened with ground tooth flanks

- Hydraulically operated disc clutch with steel / sinter friction surface

- Smooth engagement by means of adapted pressure increase during shifting

- Full power transmission and identical reduction in both output senses of rotation

- Integrated oil sump

- Common circuit for operating oil and lube oil

- Oil pump and oil filter accessible from the outside

- Fitted heat exchanger for cooling water inlet temperature of max. 32 °C, seawater resistant

- Fitted manometer for operating pressure as well as connection for remote supervision of pressure and temperature

- Control valve with electric operation

- Input: free shaft end with taper 1:30

- Input flange (WLS/U)

- Output: forged-on flange

- Paint coating with synthetic resin varnish. Colour: RAL 7001 silver grey

- Rigid mounting

- SAE bell housing

- Output: counter flange

- Flexible coupling

- Supervision instruments

- Spare parts kit as per classifications rules

- Trolling propulsion system (ADS)

- Auxiliary drives (PTO and PTI)

- Control valve with mechanical operation

- Resilient mounting

- Special reduction ratios

Options WLS 234/1 – 430/1

The gearboxes can be fitted with an additional Power Take Off or Power Take In (application: hydraulic pumps and generators).

All gearboxes can be supplied with additional supervision instruments, according to classification requirements, enabling the operator to take all necessary information from the bridge.

Monitoring of all key data for maintenance purposes.

Options WLS 730/1 – 2240

The gearboxes can be fitted with additional Power Take Off or Power Take In (application: hydraulic pumps and generators).

The output shaft can be prepared with centre bore for all common CPP systems, including connection for oil distributor box on the engine side. For free‐standing applications only.

All gearboxes can be supplied with additional supervision instruments, according to classification requirements, enabling the operator to take all necessary information from the bridge.

Monitoring of all key data for maintenance purposes.

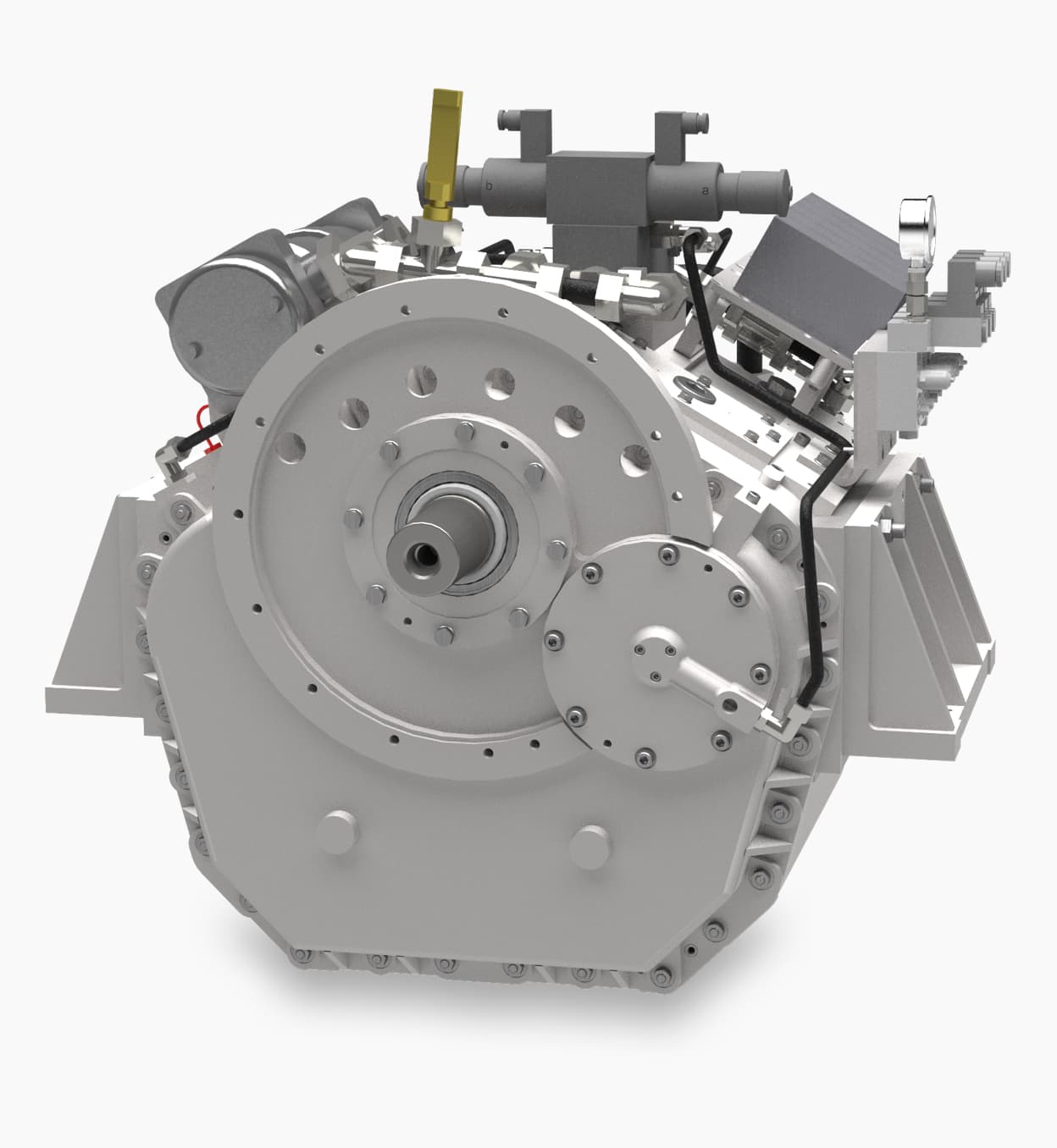

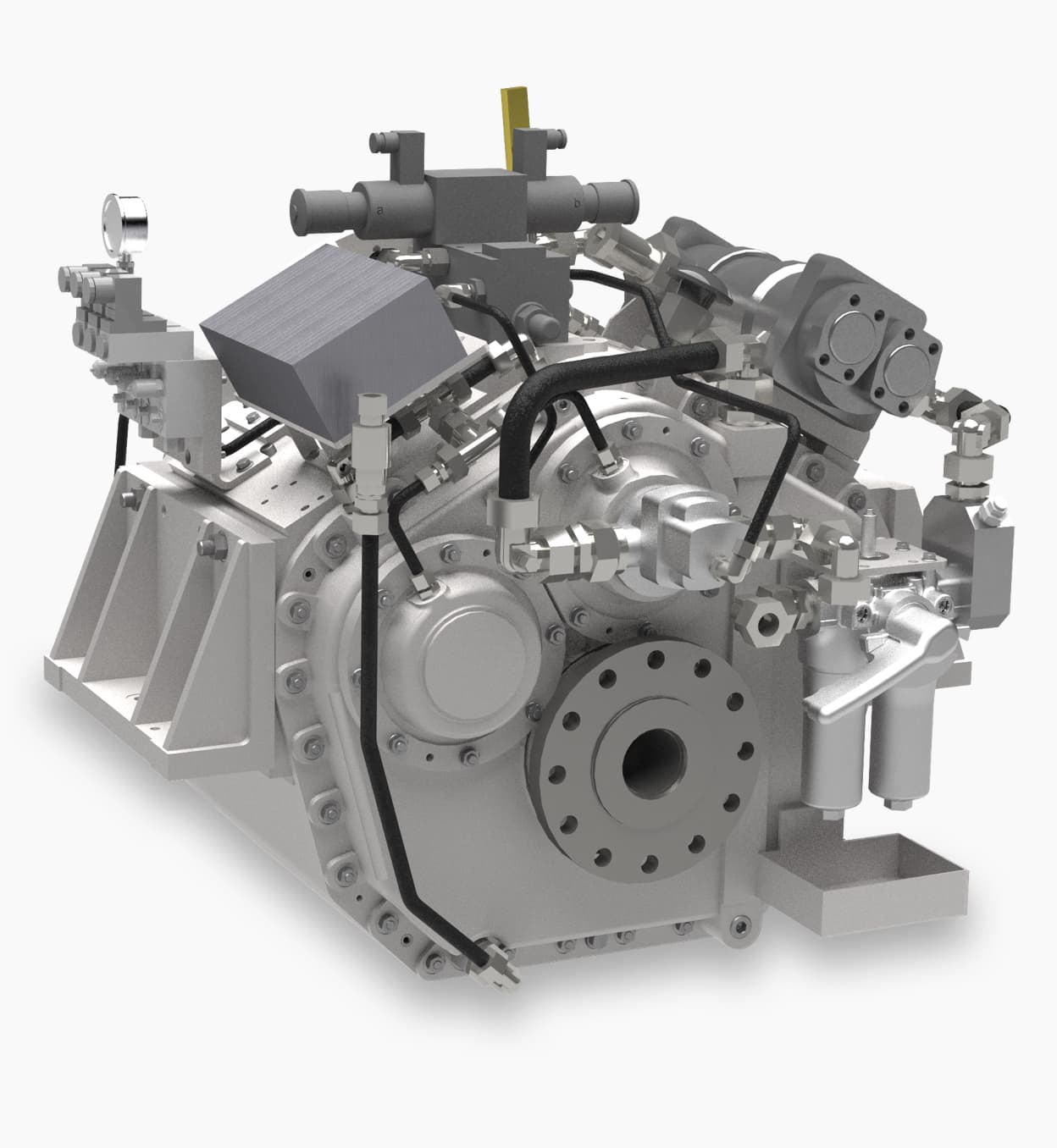

Impressions